You want the best price for your market, but you worry about poor quality. Finding the right balance between cost and durability is very difficult for many buyers.

The main factors influencing PVC flooring prices are raw material quality (virgin vs. recycled), total thickness, wear layer depth, and certifications like BWF1. Additionally, production volume2, stock availability, and manufacturing efficiency directly impact the final cost per square meter.

I talk to many business owners in Vietnam and other countries. They often ask me why my price is different from others. They see a picture and think all floors are the same. This is not true. I will explain the real costs so you can make better decisions.

What are the main cost components of PVC flooring?

You see a very low price, but the floor breaks quickly after installation. This hurts your reputation with your customers. You need to know what you are actually paying for.

The biggest cost driver is the raw material. Virgin PVC costs more but lasts longer than recycled material. Labor, energy, and additives like fiberglass also make up the total factory cost.

Raw Material Quality

The most important part of the price is the PVC material itself. In my factory, we have two choices. We can use virgin material, or we can use recycled material. Virgin material is new. It comes directly from the chemical plant. It is pure. This material is stable. It does not shrink easily. It holds color well. However, it is more expensive to buy.

Recycled material is different. It comes from old plastic products. It is much cheaper. This lowers the price of the finished floor. But there are problems. Recycled material often contains heavy metals. It can smell bad. In hot weather, like in Vietnam, recycled floors can shrink or curl. If you sell this to a school or a gym, they will complain.

Production Additives

We also add other things to make the floor strong. We use a glass fiber mesh. This stops the floor from changing size. Some cheap factories use a very thin mesh or no mesh at all. This saves money, but the quality is bad. We also use plasticizers to make the floor soft. Good plasticizers are safe. Cheap ones can be toxic.

Cost Breakdown Table

Here is a simple look at how materials change the cost.

| Component | Virgin Material | Recycled Material | Impact on Price |

|---|---|---|---|

| Purity | 100% New | Mixed Plastic | High impact |

| Stability | Very Stable | Unstable | Medium impact |

| Smell | No Smell | Strong Smell | Low impact (initially) |

| Lifespan | 10+ Years | 3-5 Years | High impact |

When you see a price that is too good to be true, it is usually because of the material. I always tell my clients to check the sample. Smell it. Bend it. You will see the difference.

How does thickness and structure affect PVC flooring price?

Do you really need the thickest floor for every project? Paying for unnecessary thickness wastes your money. But choosing a floor that is too thin causes safety risks.

Price increases with total thickness and wear layer depth3. A 0.1mm difference in the wear layer can change the price by $0.10 to $0.20 per square meter. Thicker foam layers also add material costs.

The Wear Layer Cost

The wear layer is the clear plastic on top of the floor. It protects the color. It stops scratches. This is the most expensive part of the PVC sheet. As a manufacturer, I calculate this very carefully.

If I increase the wear layer by just 0.1mm, my cost goes up. The price difference is usually between $0.10 and $0.20 per square meter. This looks small. But if you buy 10,000 square meters, it is a lot of money. A 1.2mm wear layer is cheaper than a 1.5mm wear layer. You need to check what your project needs. A busy gym needs a thick wear layer. A small home room does not.

Total Thickness

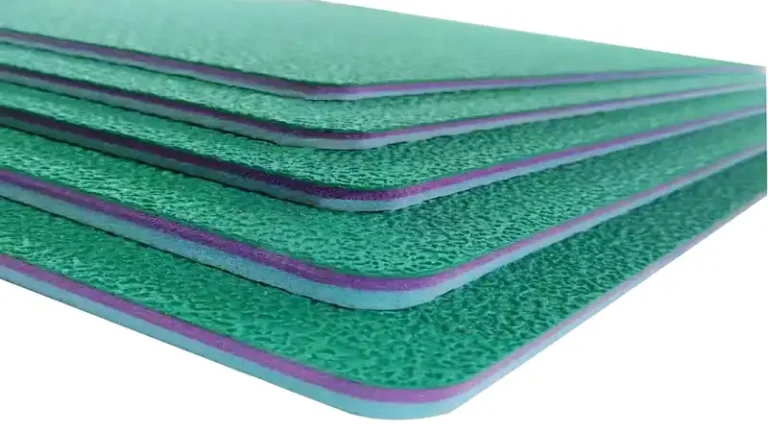

The total thickness includes the foam layer. The foam provides shock absorption. It protects the athlete’s knees. We make floors from 3.5mm to 8.0mm or more. More thickness means more PVC powder and more foaming agents. This adds weight. Heavier rolls cost more to ship.

Structure and Function

We also look at the density of the foam. High-density foam is harder. It is better for ball bounce. Low-density foam is softer. It is cheaper to make because it uses more air bubbles. But it flattens out quickly.

Thickness Comparison

| Feature | Thin Floor (3.5mm-4.5mm) | Thick Floor (6.0mm-8.0mm) |

|---|---|---|

| Wear Layer | Usually thinner | Usually thicker |

| Material Use | Less PVC | More PVC |

| Shipping Weight | Lighter | Heavier |

| Price | Lower | Higher |

I often see competitors offering a "4.5mm" floor. But when I measure it, it is only 4.2mm. They save money by cheating on thickness. At Sportaflor, we give the exact thickness you pay for. This is why our price might look slightly higher, but the value is better.

Why do PVC flooring prices4 vary so much between suppliers?

You get three quotes for the same product. One is very high, one is very low. You feel confused. Who is telling you the truth about the price?

Suppliers price differently based on their business model. Trading companies add a margin on top of factory prices. Factories like Sportaflor offer direct pricing. Stock availability and production efficiency also change the final offer.

Factory Direct vs. Middlemen

This is the most common reason for price differences. Many companies on Alibaba or Google are trading companies. They do not have a machine. They do not have a warehouse. They buy from a factory and sell to you. They must add 10% to 30% profit to survive.

I own the factory. I have 50 employees. When you buy from me, there is no middleman. You get the factory price. This helps you compete in your market. You can sell cheaper than your competitors who buy from traders.

Stock Availability

Keeping stock costs money. I have a large warehouse. I keep many rolls of different colors and thicknesses ready. This ties up my cash. However, it helps you. If you need flooring urgently, I can send it tomorrow.

Some suppliers have zero stock. They only make it when you order. Their price might be a little lower because they have no warehouse cost. But you have to wait 20 or 30 days for production. If your project is urgent, you lose the job. Time is money.

Production Efficiency

We work hard to lower our internal costs. We buy raw materials in bulk. This gives us a discount. We use modern machines that waste less plastic. These savings allow me to give you a better price. Small factories buy materials in small amounts. They pay more, so they charge you more.

Supplier Types

| Supplier Type | Price Level | Speed | Flexibility |

|---|---|---|---|

| Real Factory | Best | Fast (if stock exists) | High |

| Trading Company | Higher | Slower | Low |

| Small Workshop | Lowest | Slow | Very Low |

You need to ask your supplier: "Can I see your factory video call?" This will tell you if they are real. I am always happy to show my production line to you.

How do certifications and compliance impact PVC flooring pricing?

You want to sell to big government projects. But they ask for papers you do not have. This loses you the deal and limits your growth.

Certifications like BWF prove quality but cost money to obtain. The factory must use better materials and pass strict tests. This reliability adds value to the product and slightly increases the price.

The Value of BWF Certification

BWF stands for the Badminton World Federation. This is the top standard for badminton courts. Getting this certificate is very hard. It is not just paying a fee. It is a long process.

First, the quality must be perfect. Only reliable PVC sports flooring can pass the test. The grip must be right. The shock absorption must be exact. If I use cheap recycled material, I will fail the test. So, BWF floors always use high-quality ingredients. This raises the production cost.

The Venue Requirement

There is another cost people do not know. To get BWF certified, I cannot just send a sample piece. I must provide a specific venue. The BWF officials require that my floor is installed in a real stadium. Furthermore, this venue must have held a professional competition.

This costs me money and time. I have to sponsor events or build courts to prove my product works. This investment ensures that when you buy my BWF floor, it is world-class.

Why You Pay for Certificates

You might think certificates are just paper. But they are insurance. When you bid for a school project in Vietnam, the government asks for proof of quality. If you show them my BWF certificate, you win the trust. You can charge a higher price to your customer because the product is guaranteed.

Certification Impact

| Certification | Requirement | Price Impact | Benefit |

|---|---|---|---|

| ISO 9001 | Factory Management | Low | Consistent service |

| Fire Safety | Material Testing | Medium | Safety compliance |

| BWF | Venue & Material Test | High | Access to top projects |

If a supplier offers you a "BWF floor" for a very cheap price, be careful. It might be fake. Real quality has a cost. I provide real certificates so you can do real business.

Conclusion

The price depends on raw material purity, the thickness of the wear layer, whether you buy factory-direct, and premium certifications. You must balance these to find the best value.

-

Understanding the significance of certifications can help you ensure quality in your flooring choices. ↩

-

Investigate how production volume can affect the pricing of flooring materials. ↩

-

Discover how wear layer depth influences the cost and durability of PVC flooring. ↩

-

Understanding the factors that influence PVC flooring prices can help you make informed purchasing decisions. ↩