Choosing PVC flooring1 is confusing. A wrong choice costs money and time. This guide makes it simple, so you can choose with confidence.

The best choice depends on a few key things. Consider if it's for indoor or outdoor use. Think about the sport being played. Also, look at the material quality2 and your budget3. Getting these right ensures you get durable and safe flooring for your project.

I have been in this business for over 15 years, exporting from my factory here in Shijiazhuang. I've seen it all. Many suppliers make things sound complicated to charge you more. But the truth is much simpler. Let's break down the real secrets to choosing the best flooring for your needs. This will help you buy smart, especially for the Southeast Asian market4 I know so well. Keep reading, and I'll share what I've learned.

Should You Choose Indoor or Outdoor PVC Sports Flooring?

Worried about outdoor flooring failing in the rain? The wrong choice can lead to quick damage and costly replacement. I'll show you the simple difference.

The main difference is a special waterproof layer5. Outdoor flooring has this extra protection to handle sun and rain. Indoor flooring focuses more on things like shock absorption6 and ball bounce7 for inside use. It's a simple but important distinction for durability.

When a customer asks me for outdoor flooring, my first question is always about the weather. For my partners in Southeast Asia, this is very important. The sun is strong and the rain can be heavy. The biggest secret is not that complicated. Outdoor PVC sports flooring just has an extra layer added to it. This layer does two main things: it's waterproof and it resists UV rays from the sun. Without this, an indoor floor used outside would fade, become brittle, and crack very quickly. The top surface texture might also be a bit rougher on outdoor floors to provide better slip resistance when wet. Indoor flooring, on the other hand, is all about performance in a controlled environment. We focus on the perfect foam density for shock absorption6 and a smooth surface for consistent ball bounce. It doesn't need the same heavy-duty weather protection.

Here is a simple breakdown:

| Feature | Indoor PVC Flooring | Outdoor PVC Flooring |

|---|---|---|

| Main Focus | Player performance, safety | Durability, weather resistance |

| Waterproofing | Not required | Essential, has a waterproof layer5 |

| UV Resistance | Low | High, has a UV protective layer |

| Surface | Smooth for ball bounce | Often textured for slip resistance |

| Best Use | Gyms, badminton courts, halls | Tennis courts, multi-sport areas |

What Are "Summer" and "Winter" Formulas in PVC Flooring?

Heard about special 'summer' and 'winter' formulas? It sounds complicated and maybe expensive. I will tell you the simple, honest truth behind this industry term.

These formulas are just about the flooring's hardness. 'Summer' formula is made harder to resist expansion in the heat. 'Winter' formula is a bit softer to stay flexible in the cold. It’s not a big secret, just a small adjustment for climate.

Many manufacturers keep their exact formulas a secret, and we are no different. But the concept of "summer" and "winter" versions is something I can explain easily. All materials expand when hot and shrink when cold. PVC is no exception. In a hot climate like in Malaysia or Thailand, a standard PVC floor can become too soft and expand. This can cause it to bubble or warp after installation. To prevent this, we create a "summer formula." Honestly, it just means we make the flooring a bit harder and more rigid. This reduces how much it expands in the heat, so it lays flat and stays stable. For a cold climate, a "winter formula" is slightly softer. This is so it doesn't become too brittle and crack during installation or use in low temperatures. For all my customers in Southeast Asia, the "summer" formula is almost always the right choice. It provides the stability needed for the year-round warm weather. It is not about a magical ingredient; it is about simple physics and making a practical product.

| Formula | Key Characteristic | Best Climate | Main Benefit |

|---|---|---|---|

| Summer Formula | Harder, more rigid | Hot climates (e.g., Southeast Asia) | Resists heat expansion, prevents bubbling |

| Winter Formula | Softer, more flexible | Cold climates | Prevents cracking in low temperatures |

How Can You Judge PVC Flooring Quality on a Budget?

Afraid of buying cheap flooring that falls apart? You need good quality without the high price tag. I will show you some simple tricks to check.

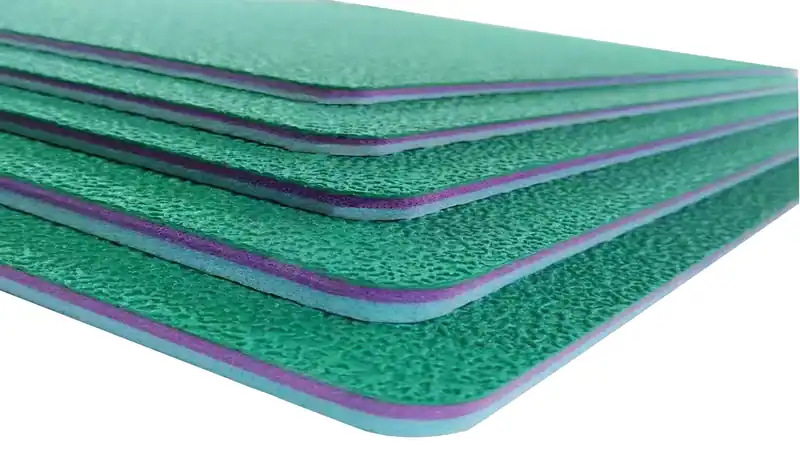

Look closely at three things: the wear layer thickness8, the foam layer density9, and the material's flexibility10. A thicker wear layer and denser foam mean better durability. Good flooring should also bend without cracking. These checks help you find value for your money.

As a distributor, you need to provide good products to your customers but also make a profit. You don't always need the most expensive, BWF-certified flooring for every project. Here are some simple, physical tests you can do with a sample to judge its quality.

The Wear Layer is Key

The top, clear layer is called the wear layer. It protects the printed design and the rest of the floor from scrapes and traffic. The thicker it is, the longer the floor will last. A cheap floor might have a 0.2mm wear layer. A good quality one will have at least 0.4mm or 0.5mm. You can't always see the difference, so you must ask the supplier for the specification sheet. This is the most important factor for durability.

Check the Foam Layer

The foam layer provides shock absorption6. High-density foam is better. A simple way to test this is to press your thumb hard into the foam on the back of the sample. If it bounces back quickly and leaves no mark, the density is good. If it feels spongy and your thumbprint stays for a few seconds, the density is low. Low-density foam will compress over time and lose its cushioning.

The Bend Test

Take a corner of the sample and try to fold it back on itself. A poor-quality floor, made with a lot of filler material like calcium carbonate, will show a white stress line or even crack. A high-quality floor, made with more pure PVC, will bend easily without any mark. I once showed this to a customer from the Philippines. He almost bought a cheaper option from another supplier until we did the bend test. Their sample cracked. Mine did not. He understood the value immediately.

| Quality Check | Good Sign (Better Value) | Bad Sign (Low Quality) |

|---|---|---|

| Wear Layer | Thicker (e.g., 0.5mm) | Thinner (e.g., 0.2mm) |

| Foam Layer | Dense, bounces back fast | Spongy, leaves an indent |

| Bend Test | Bends easily, no white line | Cracks or shows a white line |

Why Is Having Stock So Important for Southeast Asian Markets?

Tired of waiting weeks for your flooring orders? Long delivery times mean lost projects and unhappy customers. We built our business to solve this problem.

In Southeast Asia, projects move very fast. Distributors need flooring right away to win jobs. Having a large inventory11 of ready-to-ship products is a huge advantage. It helps our partners close deals quickly and keep their customers happy. Speed is everything in this market.

After 15 years of exporting, I understand that every market is different. Some customers in Europe want custom colors and designs, and they are willing to wait 45 days for production. But this is not how business works in Southeast Asia. My partners in Vietnam, Indonesia, and Malaysia tell me the same thing: "We need it cheap, and we need it now." Projects like school gyms or community basketball courts come up suddenly. The distributor who can supply the flooring tomorrow gets the job. The one who has to wait for a factory in China to produce it loses the sale. That is why we changed our business model. We focus on producing large quantities of the most popular colors and thicknesses. We keep them in our warehouse, ready to be loaded into a container. This is a huge benefit for our distributor partners12. You can confidently bid on projects because you know we can ship your order in a few days, not a few months. Your cash flow13 is better because you are not waiting long for products you have already paid a deposit on. A distributor in Malaysia once called me in a panic. His usual supplier was delayed, and he was about to lose a big school project. We shipped his order from our stock in two days, and he has been a loyal partner ever since. In your market, having a supplier with ready stock14 is not just a convenience; it is a powerful weapon.

Conclusion

Choosing the right flooring is simple. Check for indoor or outdoor use, do simple quality tests, and work with a supplier who keeps stock. This saves you time and money.

Explore the advantages of PVC flooring to understand why it's a popular choice for various applications. ↩

Discover how material quality impacts durability and performance in flooring. ↩

Find tips on selecting quality flooring options that fit your budget without compromising on quality. ↩

Stay updated on the latest flooring trends and demands in the Southeast Asian market. ↩

Understand the importance of a waterproof layer in outdoor flooring for longevity and performance. ↩

Explore the significance of shock absorption in flooring for safety and comfort during use. ↩

Learn how different flooring types can impact ball bounce, crucial for sports performance. ↩

Understand the role of wear layer thickness in extending the life of your flooring. ↩

Learn how foam layer density contributes to the comfort and durability of flooring. ↩

Explore the importance of flexibility in flooring for preventing cracks and ensuring longevity. ↩

Learn how having a large inventory can benefit flooring suppliers and their customers. ↩

Explore strategies for establishing successful partnerships with flooring distributors. ↩

Learn how efficient flooring supply can improve cash flow for distributors. ↩

Discover the advantages of partnering with suppliers who maintain ready stock for quick delivery. ↩